Split.

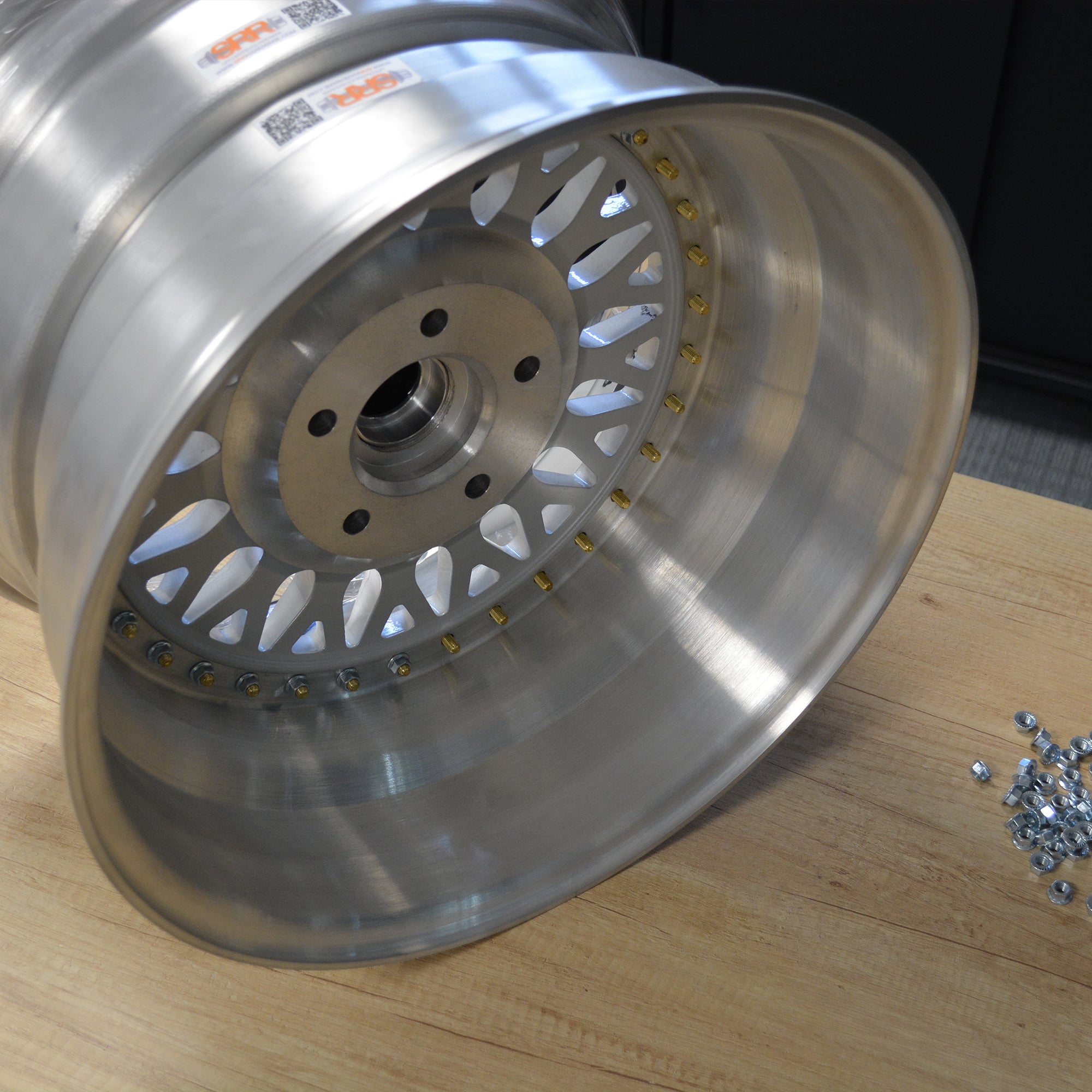

Three-piece modular wheels are typically made up of three main components: the center disc, the inner barrel, and the outer lip.

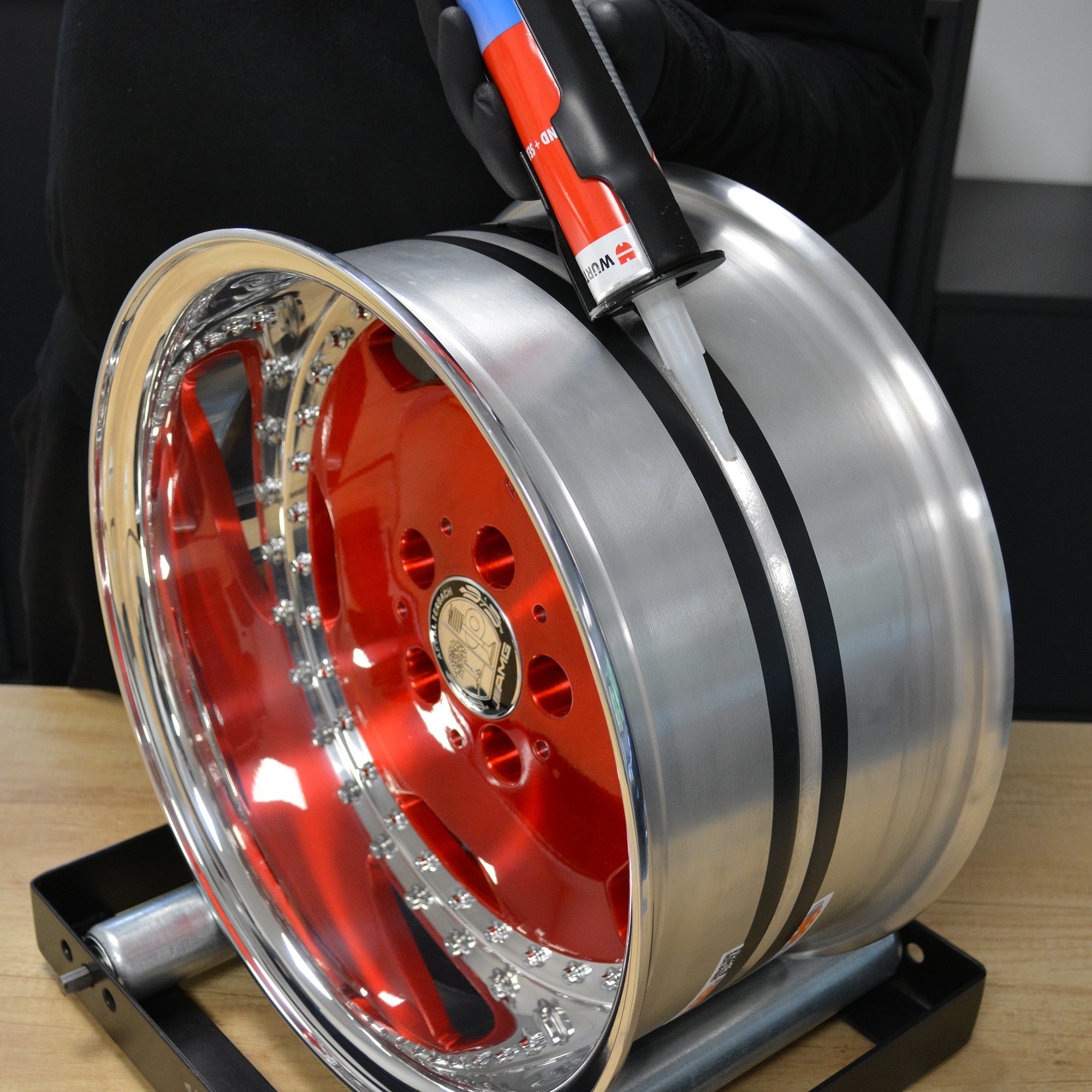

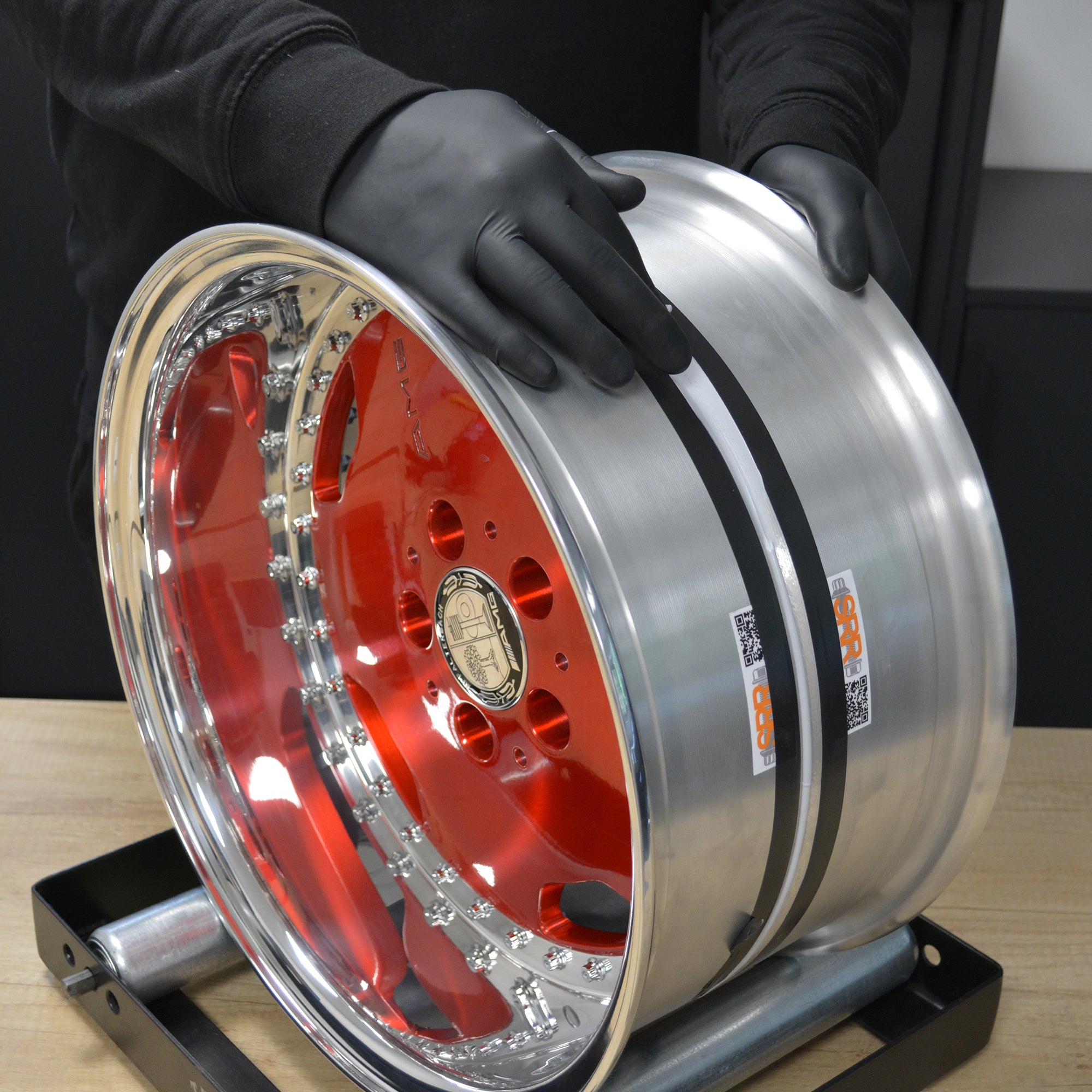

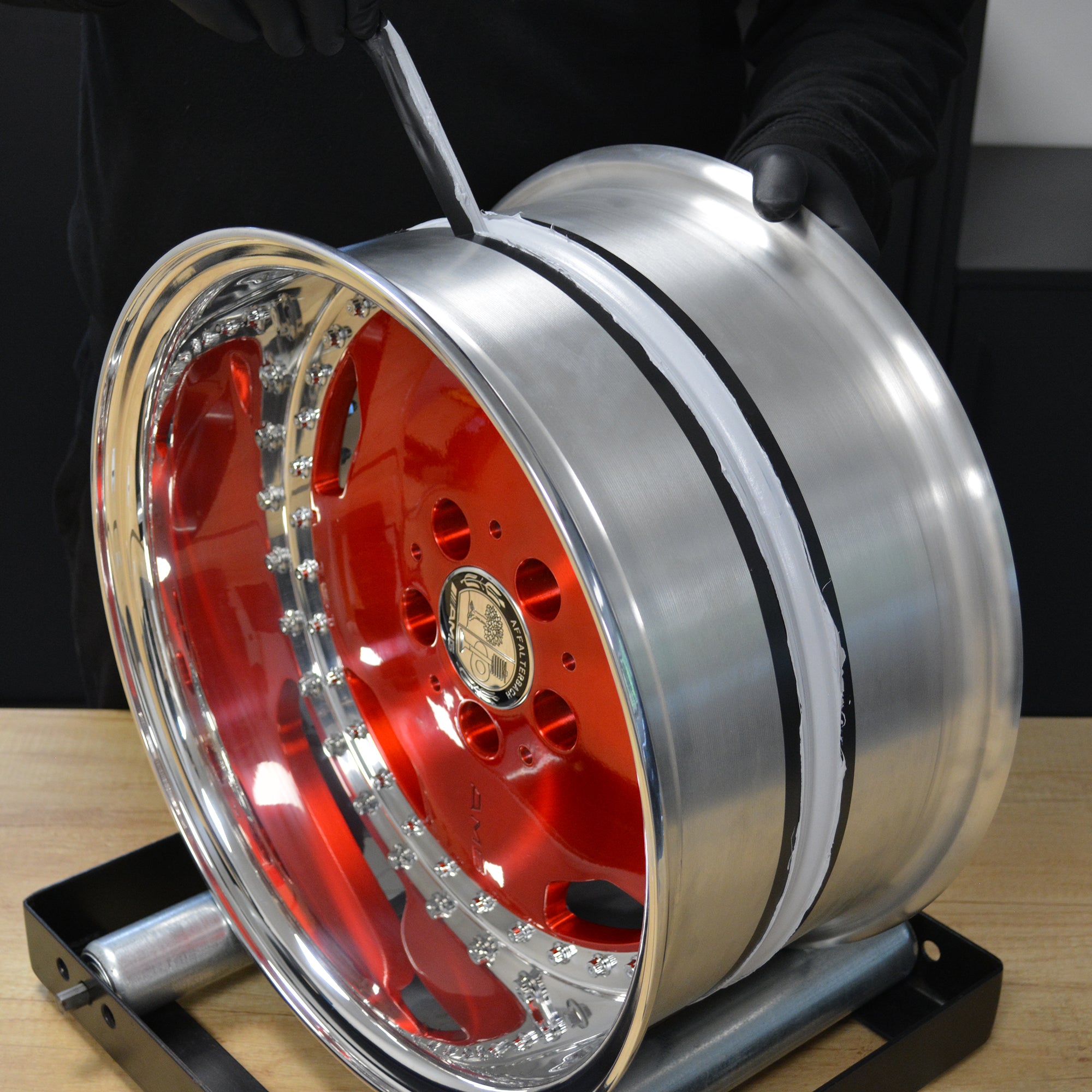

"Splitting" in this context may mean separating or taking apart these components, often for maintenance, customization, or repair purposes. It can also refer to the act of disassembling the wheel to access the inner components.

Here's a breakdown of the components in a three-piece modular wheel:

- Center Disc: This is the central part of the wheel, where the hub attaches. It's the part that bolts to the vehicle.

- Inner Barrel: This component connects the center disc to the outer lip. It's the part that connects the center to the outer edge of the wheel.

- Outer Lip: The outermost part of the wheel is the lip. It provides protection to the rim and adds to the visual aesthetics of the wheel.

"Splitting" these components is often done when someone wants to clean, repaint, or customize their wheels, or if there is a need for repair or replacement of any of the parts. It can also be part of the process when changing the offset or width of the wheel to better fit a specific vehicle or achieve a particular look.

However, it's essential to have the necessary tools, skills, and knowledge to safely and properly disassemble, modify, and reassemble three-piece modular wheels to ensure the structural integrity and safety of the wheel when it's back on the vehicle. If you're not experienced with this process, it's often recommended to seek professional assistance or consult with a specialist in wheel customization and maintenance.