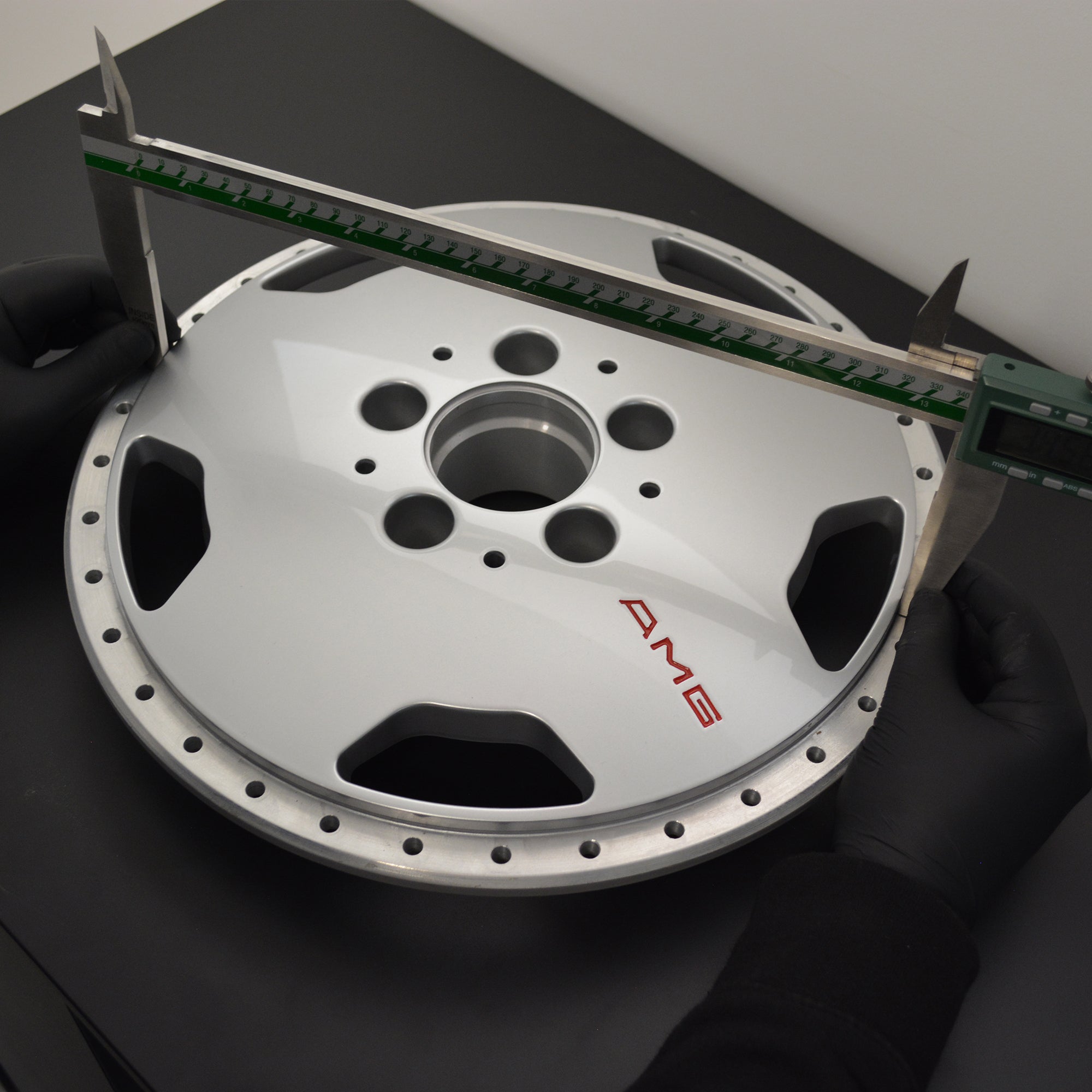

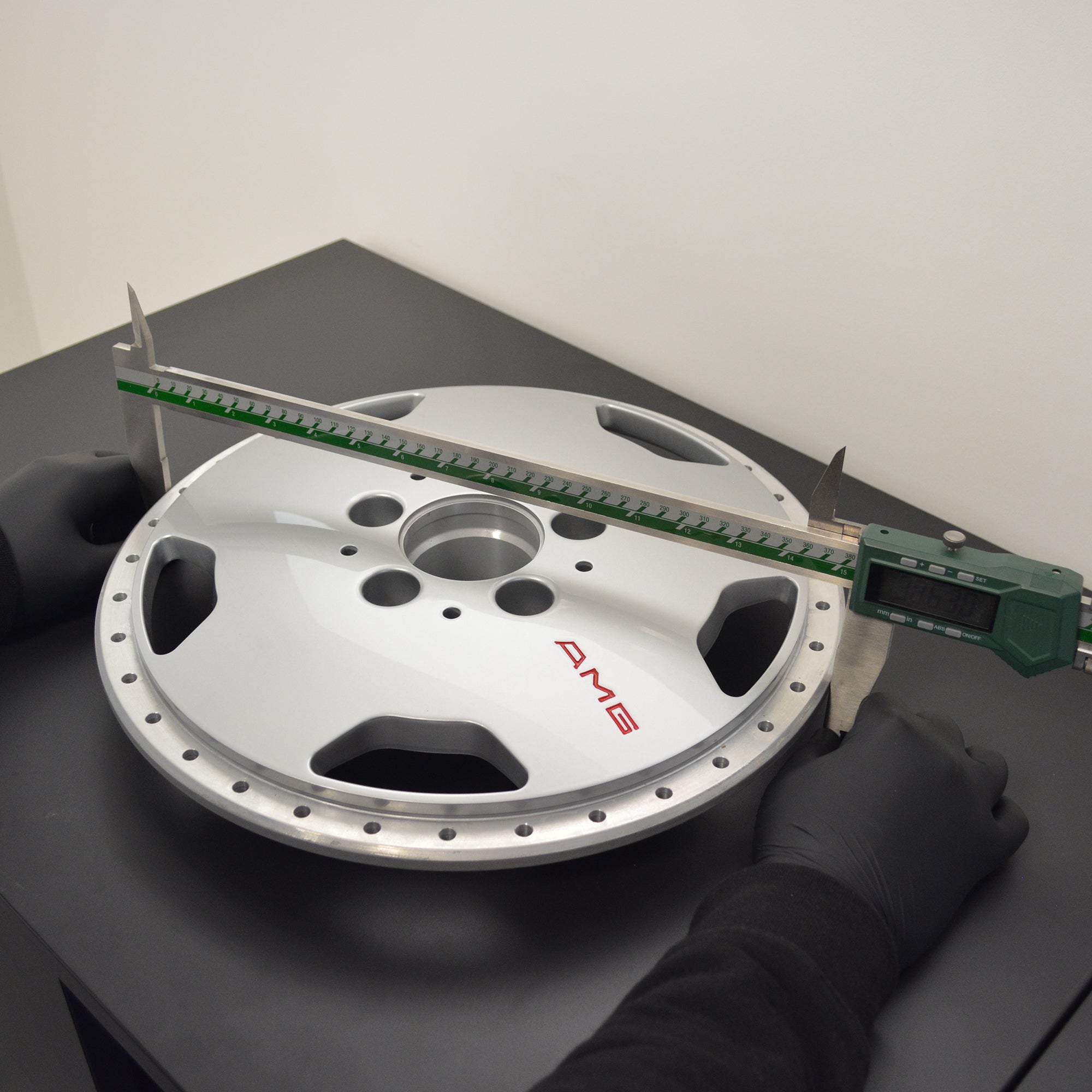

How to measure: PCD. (Pitch Circle Diameter).

To measure the PCD (Pitch Circle Diameter) of a wheel, you will need a few tools and to follow some specific steps. The PCD is a crucial measurement that specifies the number of bolt holes on a wheel and the diameter of the imaginary circle that passes through the center of these bolt holes. It is essential to determine the correct PCD when selecting wheels or adapters to ensure they fit your vehicle. Here's how you can measure the PCD of a wheel:

Tools you will need:

- A ruler or measuring tape.

- A PCD gauge tool (optional but recommended for accuracy).

Steps to measure the PCD of a wheel:

- Choose the Bolt Holes: The first step is to select any bolt hole on the wheel. You don't need to measure all of them; one bolt hole is sufficient.

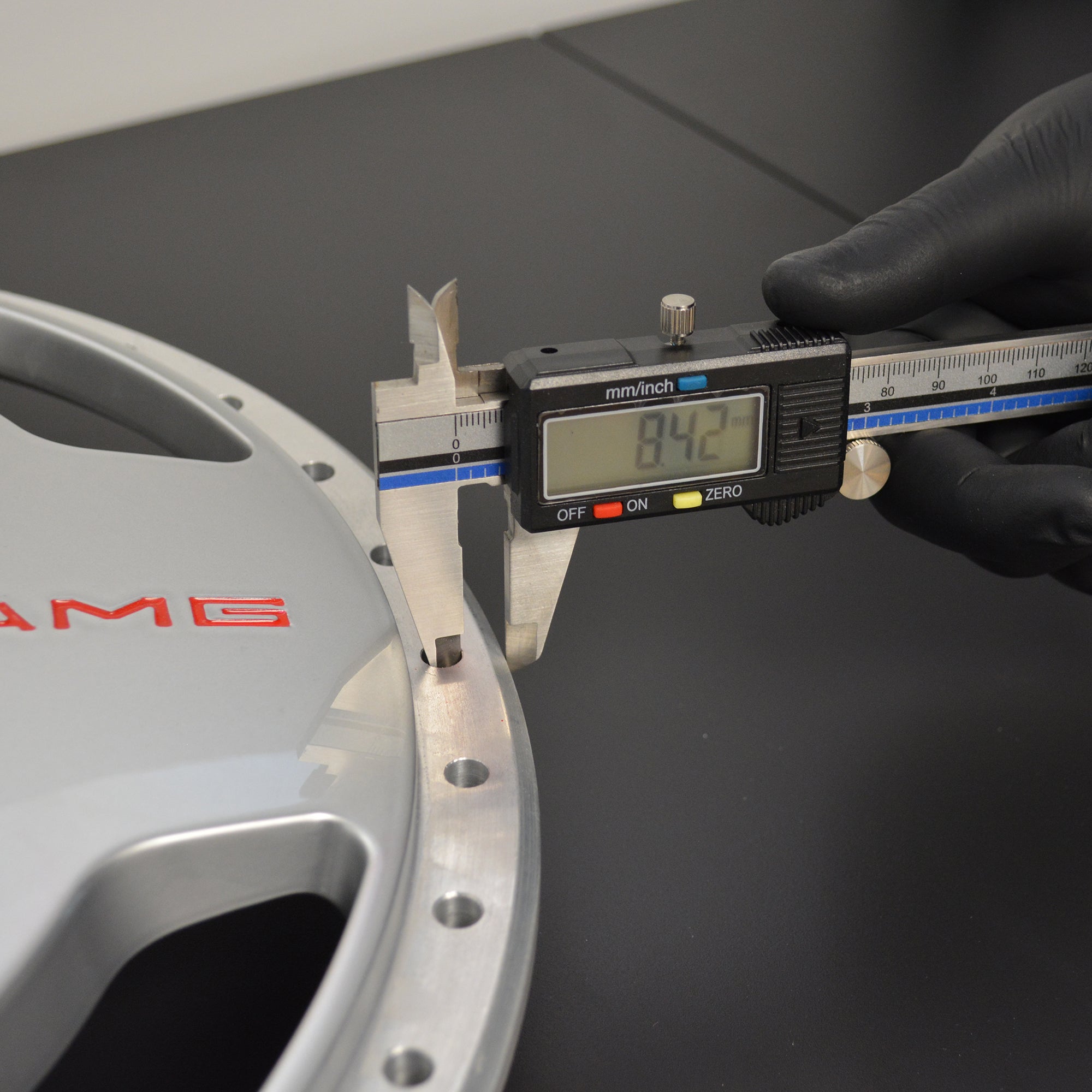

- Measure the Distance: Use your measuring tape or ruler to measure the distance from the center of the selected bolt hole to the center of an opposite or diagonally opposite bolt hole. Ensure that you measure from the center of the bolt holes, not from the edges.

- Repeat the Measurement: To verify the accuracy of your measurement, repeat the process from another bolt hole to a diagonally opposite one. This helps reduce the risk of measurement errors.