Thanks for sharing your rating with us and the community. Tag us in your build on Instagram @srrhardware

Final product looks great!

Me encanto

Thanks so much for taking the time to leave us a 5-star rating, it’s much appreciated! Tag us in your build on Instagram @srrhardware

We look forward to seeing the final product!

Gold - M7 32mm

Thank you for your feedback. We welcome your business again. Tag us in your build on Instagram @srrhardware

We look forward to seeing the final product!

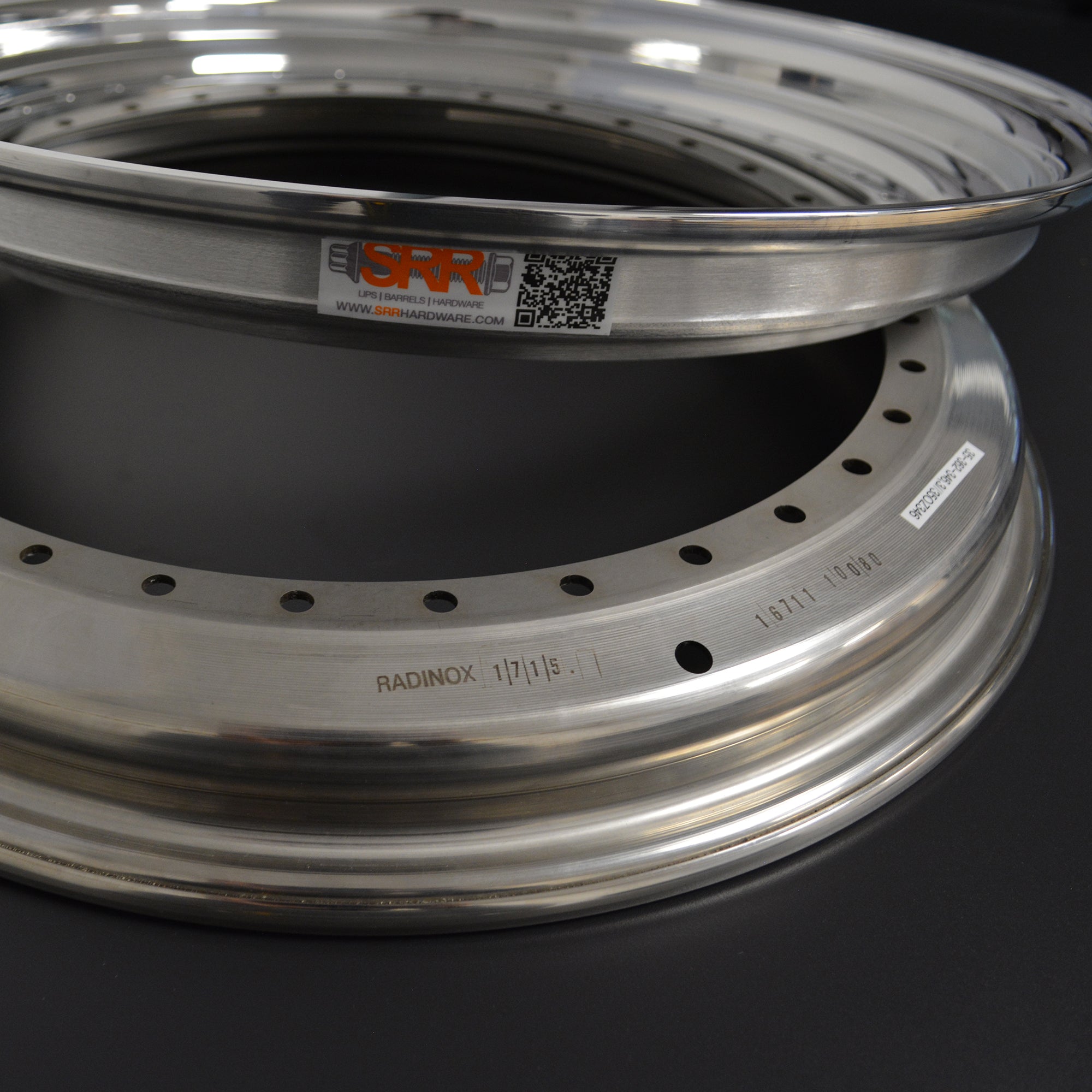

lovley quality

We greatly appreciate your loyalty to us and thank you for sharing your experience with us! Tag us in your build on Instagram @srrhardware

We look forward to seeing the final product!

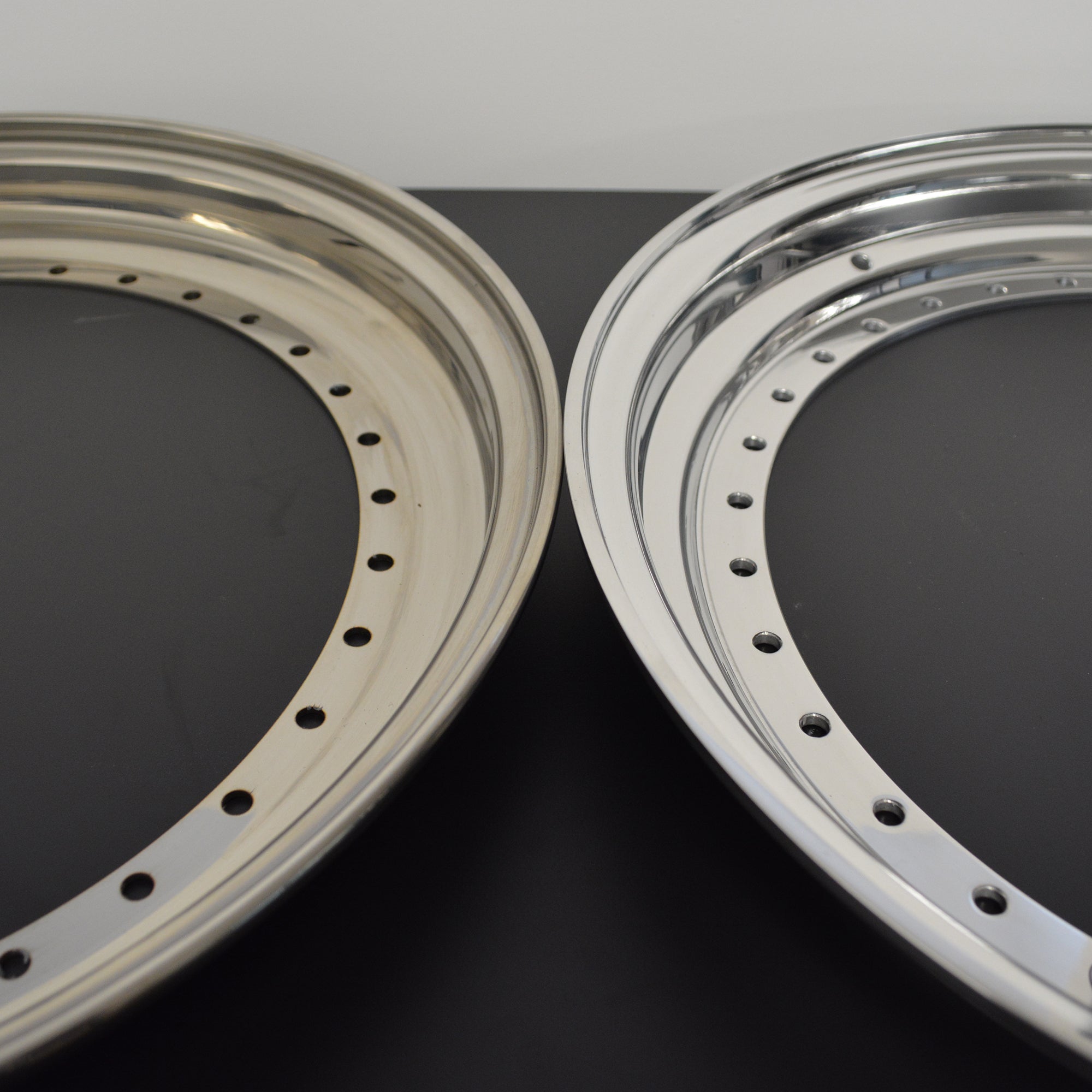

Good quality product!!! Highly recommended!!!

Thank you so much for taking the time to leave an excellent rating. We really appreciate your business. Tag us in your build on Instagram srrhardware

We look forward to seeing the final product!